Spotlight on Success: Olsun Electrics

September 16, 2016Olsun Electrics Replaces a 1954 Westinghouse 500kVA Transformer Core & Coil

We are happy to b ring you our Spotlight On Success series. We want to highlight stories from around the industry where a customer has a unique problem and a company provides a newsworthy solution. In today’s blog, we are highlighting Olsun Electrics for the great solution they provided an East Tennessee medical center.

ring you our Spotlight On Success series. We want to highlight stories from around the industry where a customer has a unique problem and a company provides a newsworthy solution. In today’s blog, we are highlighting Olsun Electrics for the great solution they provided an East Tennessee medical center.

Over the last fifty years, this medical center has made calls in regards to renovations – mostly modifications for expansion. However, sometimes circumstances force a call for work or repair unrelated to any plans. The medical center phoned to see if Olsun could offer a Core & Coil replacement unit for a 1954 Westinghouse 500kVA transformer with 13.8kV primary and a 208V Wye secondary due to a water disaster. A unit failed when a overhead kitchen drain broke and a deluge of water leaked on the transformer. It left the Nema1 enclosed unit coated with gray water, shorted two of the three coils, distorted the secondary bus assemblies, and tripped the 13.8kV main. Not the phone call that anyone is happy to be make. Yet, Olsun said, “We can do that” and began to work on a solution. EMR visited the site and surveyed the damage firsthand.

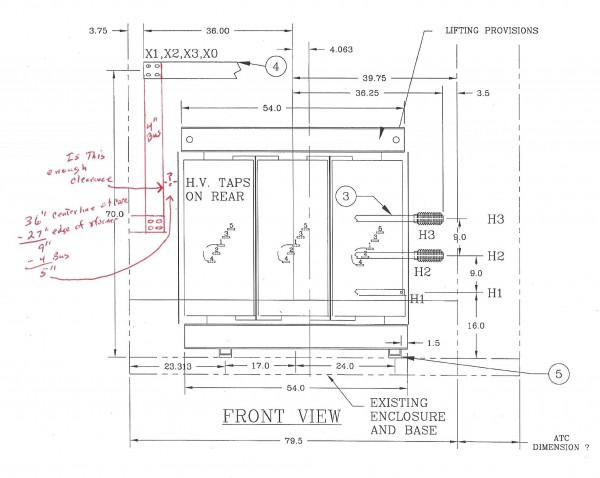

To determ ine what solution Olsun could employ to replace the unit, lots of measurements, photos, application discussions and conference calls were on the agenda. Meetings to discuss footprint constraints, fit issues and site drawings helped to conclude that Olsun could deliver. Although it would not be easy, the team formulated a plan of action by presenting themselves four problems to solve.

ine what solution Olsun could employ to replace the unit, lots of measurements, photos, application discussions and conference calls were on the agenda. Meetings to discuss footprint constraints, fit issues and site drawings helped to conclude that Olsun could deliver. Although it would not be easy, the team formulated a plan of action by presenting themselves four problems to solve.

- Problem 1 was the narrow footprint of the existing Westinghouse Core & Coil assembly. How could they work within those restraints?

- Problem 2 was the hard bus structure from the secondary of the Core & Coil to the phase bus in the low voltage section. Specifically, the customer did NOT want to replace the bus with cabling.

- Problem 3 was delivery. Even though this was a double ended sub, able to provide an alternate power source to all the load, this eliminated redundancy required to meet hospital requirements.

- Problem 4 was the opposite end of existing Westinghouse double ended sub could be paralleled for capacity if required. The new unit MUST match impedance and sequence of existing Westinghouse unit to parallel.

This would not be a simple task. In fact, two additional site visits were made. One to confirm the dimensional requirements and center points for the bus structure and a second to discuss the preliminary drawings provided with the quote to confirm centerpoints and phasing. The customer wanted to re-utilize the existing porcelain arresters on the primary side versus allowing Olsun to provide new arresters. This change required some creative bracing of input cabling to primary coils allowing for proper clearances on the primary side.

After all the meetings and phone calls, construction drawings were provided. Olsun offered quick shipment to the site which allowed the customer time to discuss their comfort level on the solution Olsun provided. The plans were agreed upon.

Afterwards, a separate company was contracted to provide replacement bus structure based on Olsun’s drawings and dimensions.

The unit shipped to spec; installed with a custom bus structure and fit precisely as planned. In the end, the customer only had to adjust ½” once the unit was on site to match the existing mounting pads and align the bus structure from site sketches, factory drawings, and customer measurements. The project was a success in the eyes of both parties.

So from disaster, a 1954 Westinghouse 500 kVA Core & Coil was retired and upgraded with a custom built replacement. The ensuing work was difficult but a great relationship was forged from the challenge.