Spotlight on Success: An Eaton Cooper Solution

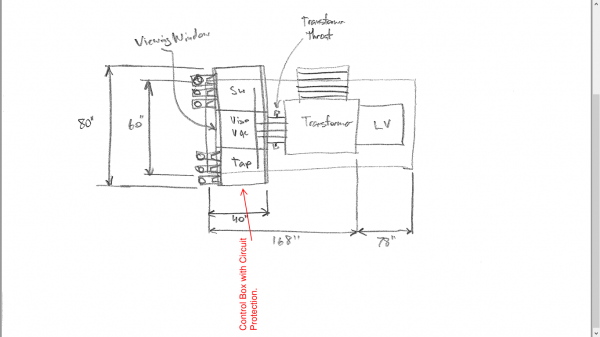

January 5, 2017For our December Power Blog, we focus on a project which highlights how an inquiry can evolve over time. We had the opportunity to work with our customer to develop a customized Medium Voltage Substation solution for a client in Tennessee. We like to show the scope of planning that these quotes utilize. In this instance, we will show you the concept sketch at the developmental stage near the end of 2015 and its progress to a finished project.

The case begins with the customer looking to replace out-dated lower interrupting rating (kA) PufferPak primary switches with a higher interrupting rating (kA) primary switch solution which was dust-tight and close coupled to a transformer and low voltage switchgear lineup. Another primary constraint was the length of the system could not exceed 246 inches (existing pad length).

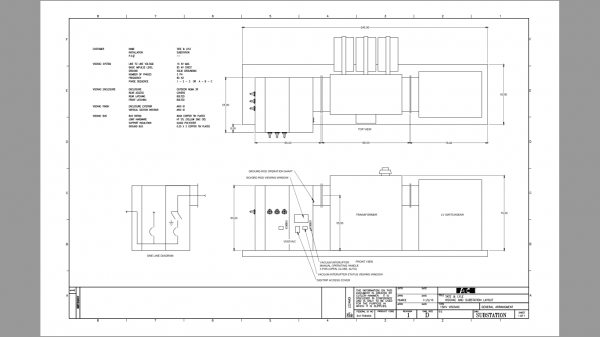

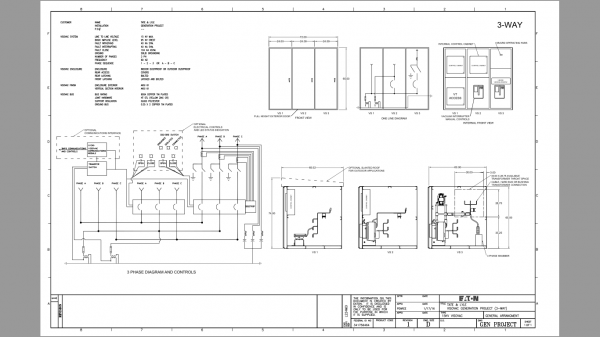

We worked with the customer to develop a simple, effective substation replacement solution allowing 40kAIC interrupting capacity with a small dust-tight footprint and isolatable / feed-through capability. This offered the ability to feed the substation from multiple directions when other circuit isolating equipment was operated.

Originally, the Eaton Cooper Visovac solution was offered to meet the 40kAIC need and to meet all other requirements. However, customizations were required. Customer advised they needed to be able to remove the transformer from the High Voltage Switch and Low Voltage Section if the transformer failed or needed replacement. The customer wanted to monitor the switch position of the primary switch and ensure circuit protection from overloads would isolate the primary switch.

The customer contracted with an engineering consultant to generate specifications and one-line drawings in early 2016, this design showed the campus redundant distribution system to provide A or B source power to the loads while isolating a single substation for replacement / upgrade / repair. The resultant quote allowed all the requirements to be met, providing flexible retrofit-ability to existing transformer / Low Voltage equipment lineup with only slight modifications to the output connection method from each Eaton Cooper Visovac to Eaton Cooper Transformer assembly. Most substation lineups will be changed out wholly, however some will be primary switch changed only where transformer is already new or recently replaced. A flexible design had to be developed to accommodate both scenarios.

The configuration advanced from a standard upright model to the drawings you see below.

As always, working closely with the client to ensure all requirements are met or exceeded allowed us to deliver a quality product, engineered to the customer’s needs.

In the event you or your business are in need of troubleshooting options for an upgrade or a new system, be sure to contact EMR and we’ll work to deliver a solution that matches your needs.